Making custom jewellery whilst social distancing for over a decade

10th April 2020

Due to the current situation I thought I would share with you some rings that I have designed and made for a customer who lives thousands of kilometres away and I have never met. The first ring I made in 2008 and the most recent in 2019. The ultimate social distancing whilst making bespoke jewellery and I have been doing it for over a decade.

Above are photos of the first ring I made for her back in 2008. This was her engagement ring and I have since made her wedding and eternity rings. Lets first have a look at the process I used in 2008 and then the the current process is used in 2019 for her most recent ring.

Designing from a distance back in 2008

Designing in Photoshop back in 2008

The customer initially emailed me a photo of a design she liked. In the above photo you can see the desired design that the customer wanted at the top. The bottom ring is that design scaled to her finger size and a diamond that suited her budget.

Preparing for the wedding ring in Photoshop

When I was an apprentice we were taught to hand sketch all our designs to scale. In 2008 a design often started with a rough sketch but almost always ended up progressing into Photoshop. This process was not as exact as the one used today but was far better than just relying on a sketch.

Even back in 2008 I was always planning for the desired wedding ring whenever I designed an engagement ring. When the time came to make the wedding ring the we were ready to go.

Now lets have a look at how the design process has evolved since 2008. It is far more accurate and when I look back at those images from 2008 it really stands out.

Designing in 2019

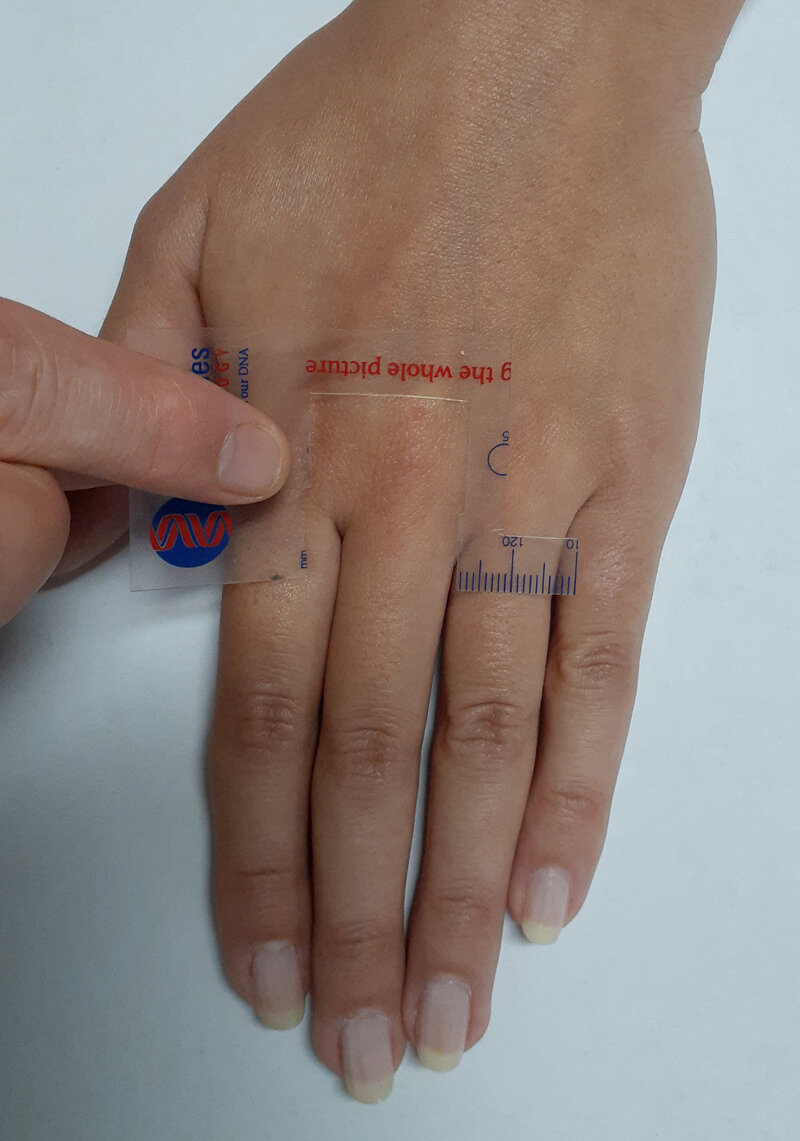

In the end it is all about how the piece of jewellery will look on you. Today for a ring design I usually I start with two photos of the customers hand as shown above.

The first photo is of their hand directly from above with a ruler. The second photo is taken, without moving the camera as much as possible, with the ruler removed.

The ruler allows me to work accurately to scale, Without it I have know idea of the customers hand size. Especially with diamonds size and scale is critical. when quoting The difference in diameter between a half carat diamond and a one carat diamond is less than 1.5mm. I use the same process for earrings and pendants.

I can then stack these two photos in Photoshop and use the ruler to scale everything to give a true and accurate representation of our design on her hand. Once I have everything to scale I then hide the image of the ruler and use the hand only photo to show the design to the customer.

However the biggest change in the design process today is that I can truly bring the piece of jewellery to life and show the design in 3D to the customer.

The latest ring in 2019 - some ideas to get started

Two of the designs sent to me by the customer

To enable me to know which direction to head with design I ask customers to provide images of designs that they like. This enables me to get a better idea of that persons taste, everyone is different.

From the photos above we had a clear direction to take the design. She liked the bar style setting and the diamond shape, size and number would be the points we would focus on.

Width first

The widest diamonds we could use in this design.

For this ring the first thing that we needed to discuss was the desired width. The ring needed to be a low profile to sit next to the other rings. There was a limit to how large we could go in diamond size. The larger the diameter of a diamond the deeper it gets.

Article: Don`t forget gem depth

As it turned out she liked the look of the layout above. We could now move on to the next design aspect.

Spacing the diamonds

3 options for the spacing of the diamonds.

From the options above the customer selected the spacing on the left for the 7 diamonds that would go into her ring.

It is the small details that make a design exactly how you want it, refined to your taste and everyone is different. You have the opportunity to do that when you make a piece of jewellery with me.

Double checking - the draft

The draft ring.

There were two reasons why the draft was so important with this ring.

1 - The draft would enable the customer to try the ring on ensuring it was just what she wanted. If anything was not right we could make changes prior to making her ring.

2- As you put three rings on the same finger they in effect become one wide ring. The wider a ring gets the tighter it will be at the same finger size. Sometimes you need to make wider rings to a larger size than a narrower ring to fit same finger.

I created a draft out of sterling silver and set some cubic zirconias into it. I also gold plated the draft after I took that photo above as the actual ring was to be 18ct yellow gold.

The draft was then posted down to the customer. Once she had viewed and tried the draft on she returned it to me using the Express Post bag I enclosed.

All done

The ring once finished was sent fully insured to the customer in Brisbane. A service I include free of charge to all of my out of Cairns customers. The rings detail are as follows.

18ct yellow gold

7 x 2.4mm round brilliant cut diamonds

F colour and Si1 clarity

.39 carats total diamond weight

There is usually a Cairns connection

Most of my out of Cairns customers once lived in Cairns or know someone who has dealt with me before. This ladies husband I knew from when I lived in Townsville many years ago. Here is a pendant I also made in late 2019 for a former Cairns customer that now lives in Tasmania.

Article: Then there were three

There are some however that trust me from a great distance without having ever met me. I truly appreciate the trust these customers place in me.

Article: A leap of faith

I wish everyone all the best as we deal with Covid19.