Only a Gemmologist would loves flaws like this.

26th January 2018

This pendant is very interesting because despite the design appearing simple the gemstone created quite a few challenges during it`s creation.

23mm x 8mm Tourmaline

Discuss

One of my longtime customers is a Gemmologist. He likes to collect gems as he travels and I get the job of making some of them into jewellery for his family. One of the things I have noticed over the years is that all the Gemmologists I have dealt with are far more forgiving of flaws in a gemstone than the retail public are.

Colour and size of the "specimen" are often more important and the flaws are looked on as interesting features of the gems natural formation.

This Tourmaline is quite large at 23mm long and 8mm wide and has some internal flaws in the centre and both internal and surface flaws at the green end. It was decided to set the gemstone green end down to minimise the visibility of the flaws. It gives the appearance of something inside the gem floating to the bottom.

The customers chain end.

Design

The first step of the design process was to measure the size of the customer`s chain that the pendant would be worn on. We would design around this to avoid the disappointment of the chain and pendant not matching.

After some discussions of designs we narrowed it down to these two. The design on the left below was chosen and with the top view confirmed we would now start designing the side view.

The design on the left was chosen.

The top of the pendant design would also serve to secure the gem. The gemstone would slip into the top of the pendant and be secured by the setting at the other end.

With a gem this long and deep the rail that it would sit on would also be very long and deep. Made solid it would be extremely heavy and ugly.

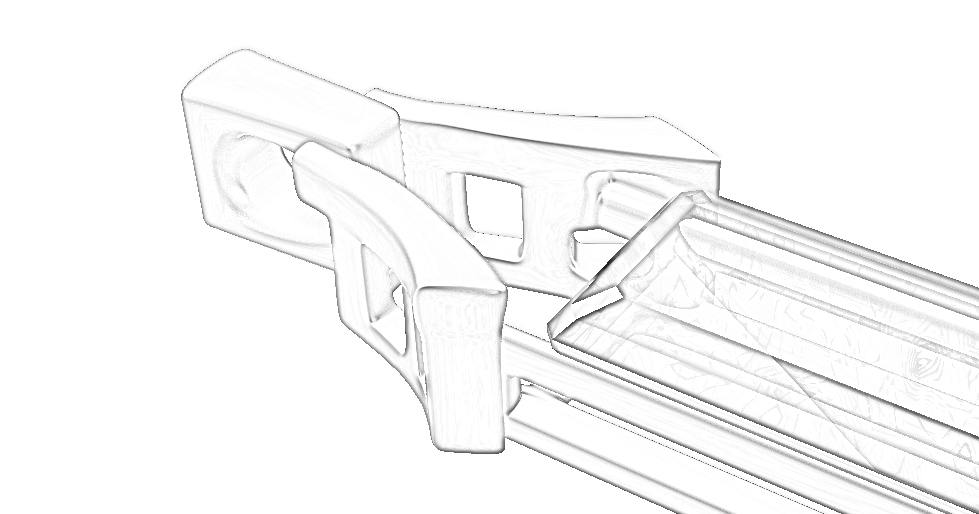

We would use two rails, one underneath the girdle of the gem and the other dropped down to match it`s depth.

Double rail side of the pendant.

I needed to add something to bridge the rails and add support. The customer approved my idea of using the top design of the pendant in the side gallery.

Top design of the pendant also used in the gallery.

Problem 1: The gem cut

With the general design finalised we now have to address some problems with the gemstone. This gemstone has a vertical cut on the ends. Normally there would be some taper allowing the rail to pass under the gemstone. With this cut that would not be possible.

Our gem shape on the left has vertical facets on the end.

The rail passing around the outside of the top end of the gem would be unsightly and without it a pendant this long could flex, something that we could not allow given that the top of the pendant also secures the gem.

Normally I would have left this end of the bottom rail open so that the gem could sit down as far as possible, keeping the pendant depth as low as possible. For this pendant I had to close it across the base of the gem.

The rail passing under the top end of the gem.

You can see from the illustration above that the gem now hits that rail. The bottom rail would now need to be dropped down to clear the gem and the gallery depth increased to match.

Flaws more prevalent at the base.

Problem 2 : Those gem flaws

We had deliberately placed the flaws at the bottom of the pendant to make them less visible. That end was however the end that would have the setting applied to it.

The process of setting a gem does by it`s nature place pressure on it. If the setting portion of the pendant applies no contact/pressure on the gem then it is loose.

With a gem that is this flawed, to a degree already broken, I would need to apply as little pressure as possible during setting. The setting method would need to be changed.

In the original design we had a plate of metal going all the way along the base of the gem. Bending that single piece of metal over the gem would be possible but risky. The gemstone was not mine and this was a risk neither myself nor the customer were willing to take.

I decided to remove metal from the middle of the setting area creating two finer claws on the ends that would be easier to bend over the gem.

Originally planned setting on the right and the modified on the left.

Deliver

If you made it this far then you now realise how much thought can go into properly creating what may at first seem the simplest of pendants.

The pendant was made in 18ct yellow gold. It is 3.7cm in length and weighed 6.2 grams excluding the gemstone.