Don`t forget gem depth

11th July 2017

Often I see pieces of jewellery that have been designed in a way that does not allow for the depth of a gem. This wedding ring remodel is a good example of this.

Must have been uncomfortable

It appears that the reason the gemstone has fallen out is because the claws have worn down. You should every year or so have your rings checked if you intend to wear them everyday.

Claws have worn of and the gem lost.

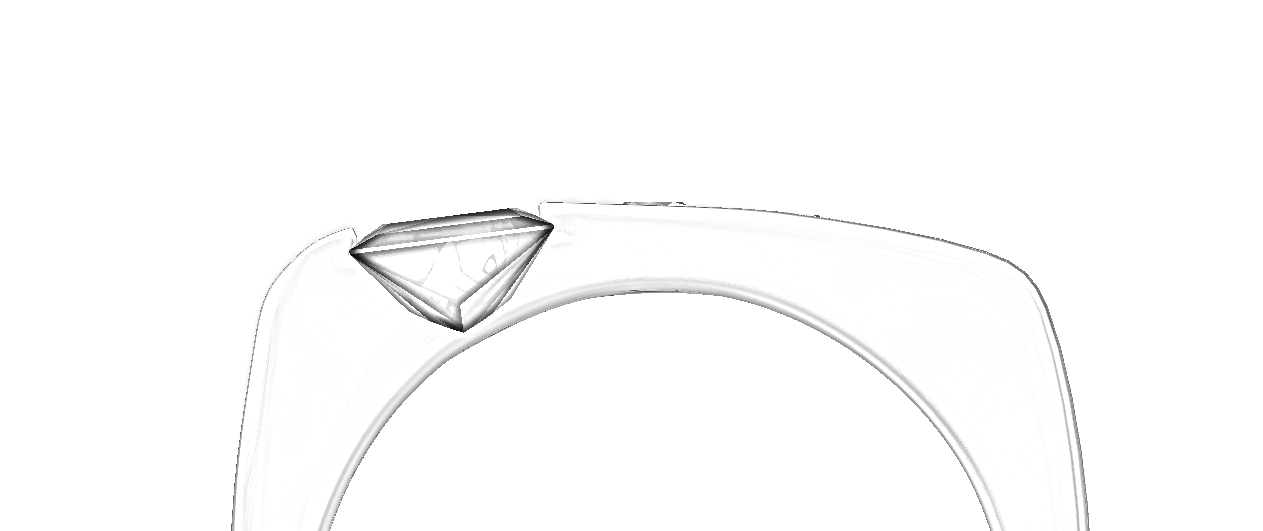

This wedding ring might look wide enough to have a gemstone set into but if we turn the ring over we can see that the ring has very little depth in the metal especially at the point which the gem is set.

Square weding ring with limited depth.

The bottom of the gem would have protruded from the ring and touched the finger. Even if this did not cause the wearer discomfort it means that the ring could never be worked on by a jeweller using a ring mandrel which we use to shape and modify rings.

In the next photo I have edited in a gem and you can see that the depth of the gem is greater than that of the metal.

Not enough depth for a gem this size.

Starting again

The customer came to me to make a new wedding ring using a 5mm square cut Tsavorite Garnet. First thing I did was warn him that this type of gem would be prone to scratching and chipping and that he would need to take care of it.

The idea was to again use a square style ring, this time with a Euro style band top and bottom that we could accommodate the depth of the gem into a corner.

Euro style band

Creating the design

This design was pretty straightforward to layout. We knew the width of the gemstone and the ring was to be just slightly wider. This was the first draft of the top design edited onto the customers hand.

Digital mockup of the ring on the hand to scale.

With the side profile I initially had the ring square as shown on the right below but after talking to the customer we softened the shape to that on the left.

Softer shape on the left was approved.

Squeezing that gem depth in

With the new design there was a limit to how far in from the corner of the ring we could bring the gemstone in. You can see in the next photo that the 5mm wide square cut gem has a depth that just makes it into the ring as we have designed it.

Bottom of the gem just clearing the finger.

The finishing touch

The customer felt the ring was still lacking something so we explored the addition of some hammer set diamonds to the top of the ring.

He printed out the previous photo of the ring on the hand I had sent to him and sketched onto it his idea of a diamond arrangement. I then digitally recreated the ring to reflect that.

The layout of the hammer set diamonds

The draft

I set an Amethyst and some cubic zirconia into the draft ready for the customers viewing. With each of the four sides being equal in length getting the finger size right the first time was all important.

The draft ring.

In the next photo you can see that as I stretched the ring up to the correct size the scrap silver that the draft was created from started to crack. It does not matter how good you are, resizing a ring damages it. Even a near prefect resize will thin a ring slightly and that is why I make sure we confirm the size with the drafts and avoid resizing a brand new ring.

The draft ring cracked during resizing.

The finished ring

A Palladium Sterling silver alloy was used for this ring. With Palladium added to the pure silver in the place of copper this Sterling Silver alloy is less prone to tarnishing.

The Tsavorite Garnet is 5mm wide and the diamonds come to a total weight of .13 carats.